From the time immemorial, people are habituated of wearing garments for protection, comfort and fashion. In this hi-tech civilization era, people are eager to showcase their fashionable modern attires as a sign of status. As a result, so many manufacturers have thrived in this industry.

ARIZ GARMENTS is one such manufacturer of the 21st century, that has made the Pandora's Box full of exclusively designed fashionable garments for all age groups. We have epitomized our brand to create timeless features that brings power to the quality and designs.

It can be said the we are the El Dorado of Indian casual-wear,Indian traditional-wear, Fusion-wear, western designs and fashionable street wear. We strongly believe that our designs bring a statement of empowerment and joy to the wearer.

In order to survive and flourish in the garment industry, we have recruited creative designers, highly experienced technicians and skilled workers. Our creativity and sense of fashion trend following has made our brand come in the race of fashionable wear.

With the Certification of ISO 9001:2015, we ensure to use the best quality of fabrics for the productions of the garments. At presently we are exporting to our neighbouring countries like Bangladesh, Sri Lanka and few of the countries in the Middle-East like UAE and Qatar.

Our goal is not just to expand the markets but also to satisfy the interests of our loyal customers, retail clients and showroom malls.

We at ARIZ GARMENTS make all efforts to supply our orders within the stipulated time-frame and endeavour to take full care of our customers with honesty and sincerity. In our organization we meet the demands of modern fashion with new tastes that exemplifies quality to excellence and genuine value.

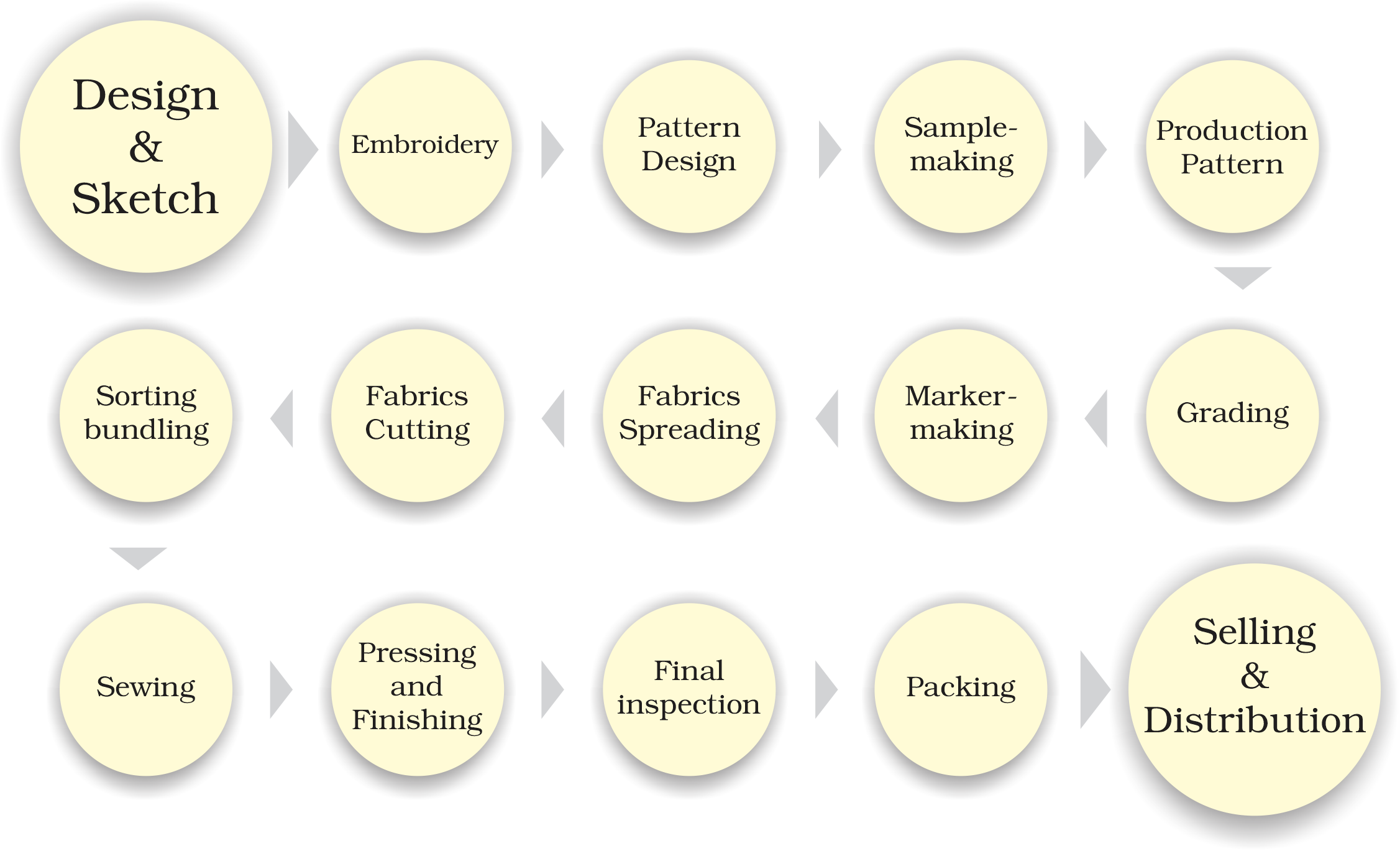

Our business purview covers a wide range of planning & operations, such as research, design, and testing and inspection of our products. We are focusing on manufacturing, supplying and exporting various types of Women & Men Fashion Garments. We are committed to maintaining our growth through honesty, integrity, and a drive for excellence.

Our top-notch products combine style and utility within the all respective segments of men & women. Our team of skilled & seasoned designers provides creative guidance to our customers on product design, texture, and color across all categories. We emphasize on ensuring consistent fabrication to produce flawless finished products. We also offer supplementary services including various types of embroidery and printing work on fabrics and completed garments.

Ariz Garments is a one stop solution for all our designers' creative needs. From conception of initial craftsmanship into final samples for collection to managing the production order. We offer you an end to end service with embroidery being our specialty. Incorporating workmanship of our exceedingly talented and driven group individuals advertising different procedures of hand weaving, machine weaving and digital/computer weaving amalgamating the artisan culture with the present day plan and its determinations.

Our designs characterize amalgamation of beautiful & aesthetic colors incorporated into trending styles. Focusing on Indian, Indo-Western and Western wear, our collections epitomize current fashion trends suiting to fit all body shapes. Apart from our ready-to-wear items, we can moreover craft custom items to meet our clients necessities and style. We routinely ship large amounts of customized clothing for all age groups based on the buyer's inclinations.

Our products are mirrors of high quality and we continually establish new benchmarks for excellence in the industry. Quality is the foundation of our success and holds utmost significance in all our endeavors. We ensure consistent quality by rigorous quality checks and controls in the procurement of raw materials, work processes, packaging, transportation and delivery. Our commitment to quality has garnered much admiration and respect from our global customer base.

Quality for us is achieved through proactive effort which is aimed at achieving excellence in all aspects. We have implemented rigorous preprocessing and validation methods to guarantee that quality remains uncompromised at every stage of our operations. Our dedication to quality has resulted in us being certified for compliance with prominent quality benchmarks such as ISO 9001:2015. We are also accredited with membership of Apparel Export Promotion Council (AEPC), Federation of Indian Export Organisations (FIEO) & National Accreditation Board for Certification Bodies (NABCB).

Our excellent products have received praise globally for their designs and finishes. We take pride in catering to some of the most well-known customers. We recognize that the customer is at the center of all our endeavors. Nevertheless, experience has shown us that these endeavors are successful only when suppliers and employees are given equal importance. Our workforce is our main priority. We foster their growth and provide an atmosphere that fosters a strong sense of belonging, like a close-knit family.

Upon the buyer placing an order, the procurement process commences by evaluating the prices and quality of fabrics, colors, and other specifications in accordance with the buyer's needs. We work with our suppliers to obtain these materials, gather them, and deliver them to the buyer based on their requests and timeline.Once the raw materials are delivered by our suppliers, we dispatch them to the buyer according to their requirements and schedule.

Meanwhile, we begin creating a design sample using the available materials, following the buyer's sketches and design instructions. As soon as the sample is ready, we send it to the buyer for feedback. Simultaneously, we notify our other suppliers to procure labels, accessories, and other items required for the marketing sample.

Upon reviewing the marketing sample, our merchandising department prepared an approximate price for buyer assessment and sent it to the buyer along with the marketing sample. Once the buyer confirms the price, style, and design by comparing it to our samples, we take note of any feedback or requested changes. Before commencing production, we created another set of samples known as production samples, which we resend for buyer's approval to start production.

Upon order confirmation and receiving letter of credit, we order our suppliers to commence manufacturing of the fabrics, accessories and trimming the materials. Alongside, we initiated production planning with our manufacturing team to ensure that production could begin immediately upon the arrival of the raw materials. We assisted our manufacturing team in configuring the machinery according to the production process, drawing from our knowledge gained during the sampling phase to make sure the production process is smooth. Additionally, we share them with a printed layout plan of the manufacturing for the product.

Prior to shipping of fabrics by the supplier, our quality inspector inspected the goods at the supplier's premises to ensure they met the buyer's specifications in terms of color, quality, and so on. If the materials were found to be as per the buyer's benchmark, they were permitted for shipment. Upon the delivery of raw materials, our quality inspector once again conducts an inventory quality check to inspect for any issues such as shading, defects or poor quality while in transit. If any inconsistency were found, we immediately notify the supplier to replace the raw materials.

We believe implementing the paper board method to control the size during fabric cutting allows us to uphold the cutting ratio, which is crucial for packing assortment. This guarantees that the goods’ packing will not be disordered or varying in size after production. We make sure to closely monitor the entire cutting process to ensure that all fabrics are cut precisely according to the buyer's instructions. Once the cutting process is complete, we carefully inspect the fabrics by placing them on the paper board to ensure that they are all aligned to the buyer's specification. In case of any misalignments, we have a contingency plan for prompt rectification.

Throughout the manufacturing process, our quality inspector carefully examines each step in the whole manufacturing process and makes corrections as needed. In-case of any errors, they provide guidance to the operator on how to rectify them. This ensures that after all the operations, the garments would match the sample in terms of measurements, design, color, labels and more.

Once production is complete, the goods are brought to the inspection table. Thorough inspections the quality control team check for open stitches or inaccurate trimming. Tire checked pieces are then sent to the packing section where they meticulously pack them into carton boxes. A QC member oversees the packing, assortment and quantity using a checklist. Once all cartons are prepared for the shipping are once again checked before the final inspection.

The final inspection is mostly conducted by our head and sometimes by the buyer.

Once the final inspection is done, the goods are approved for shipment. Our shipping department handles the cargo until it reaches the buyer's destination and inspects tlie cartons before handing it to the logistics vendor for shipment.

We operate through our own manufacturing unit. We have also subcontracted with other factories which we have been working with for a long time, producing both Woven, Knitwear, Leather Garments and Accessories

Our skilled team of designers and dedicated artisans produce luxury fashion apparel for both men and women. We prioritize developing cutting-edge design concepts, superior embroidery, and innovative garment production. We assist our clients in exploring creative options for product design, texture, and color choices.

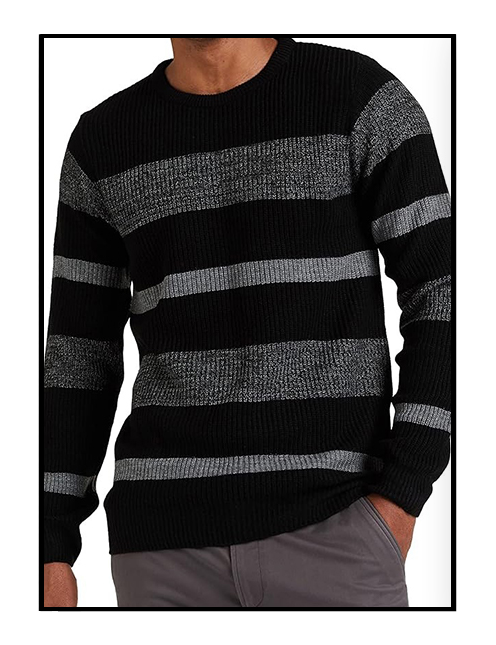

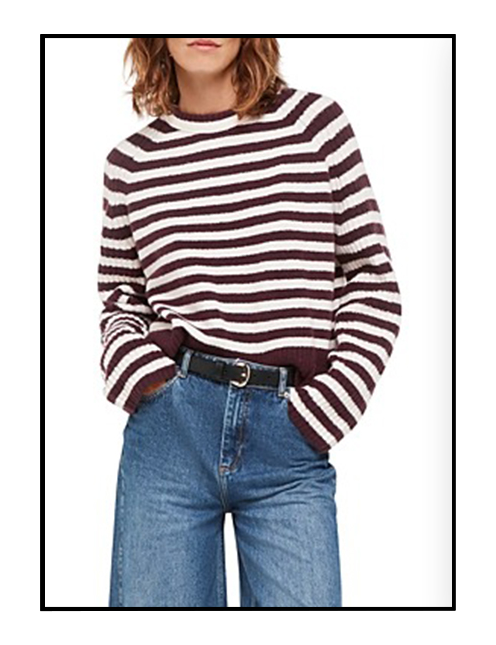

Our men's wear range is made from high-quality fabrics using advanced technology, creating a perfect blend of style and comfort. Our planning makes sure to keep consistent fabrication for a flawless finish.

Our of men's wear is available in a wide variety of colors, designs, and styles which includes:

Our men's wear range is made from high-quality fabrics using advanced technology, creating a perfect blend of style and comfort. Our planning makes sure to keep consistent fabrication for a flawless finish.

Our of men's wear is available in a wide variety of colors, designs, and styles which includes:

.jpg)

.jpg)

.jpg)

Our highly skilled craftsmen craft top-notch hand stitched embroidery designs on fabrics, showcasing luxurious craftsmanship. We also use advanced machinery for our other productions to create a sleek appearance and ensure durability that lasts. The special fabrics we procure ensures breath-ability, while the high-quality colors preserve the garment's appeal over time. We specialize in offering a range of high-end designs for:

Our range of Indian attire is designed to provide comfort & durability. These garments are made from soft, plain fabric and feature simple yet attractive designs for ultimate relaxation with eye-catching details. The range of Indian Wear that we offer is:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Our range of woven garments are soft finish and unique designs are standout features of our woven clothing. Which comes in a variety of vibrant colors and appealing designs, crafted from the highest quality materials to ensure maximum comfort for both.

.jpg)

.jpg)

.jpg)

We source our Sweaters & Cardigans from Ludhiana, a city located 1,900 km from Kolkata and famous for its sweater industry. Our vendors offer different types and qualities - such as Mohair Sweaters, Cashmere Sweaters, Fleece Sweaters, Acrylic Composition & 100% cotton with different combinations and compositions. The factories are fully equipped to provide the latest work such as embroidery, printing, dyeing and fading. This is all at an extremely accessible price.

Our specialty is high-end leather jackets and accessories. We source only genuine leather and cany out meticulous quality inspections to guarantee outstanding durability and craftsmanship. You can rely on us for unmatched style and quality in every piece.

Our dedication to quality goes beyond what we produce. We place a high value on ethical sourcing and sustainable procedures, guarantee that the leather we use is not only premium but also sourced ethically.

.jpeg.jpg)

| Merchandiser | 5 |

| Pattern Master | 1 |

| Sample Man | 2 |

| QC | 15 |

| Designer | 3 |

| Administration & Marketing | 3 |

| Total Employee | 29 |

| Name: | Shamim Parvez Hazari |

| Contact No.: | +91 98842 99981 |

| Contact No.: | +91 98313 51315 |

| Email: | md@arizgarments.com |

OUR CSR PHILOSOPHY: In our opinion, corporate social responsibility, or CSR, is the need to conduct business in a way that is ethical, socially conscious, and environmentally beneficial. Consequently, this fosters the country's social and economic development.

OUR CSR MISSION: As part of our CSR mission, we have determined the following target areas:

Encouraging Education and Vocational Training

A few things need to be kept in mind after sampling and production procedures. The following principles explain the general guidelines that we adhere to when creating our schedule:

Note: Fabric providled for a single style should not be utilized for protosamples; rather, it should only be used for salesman samples. Incase of an extra sample, buyer need to inform us how many salesman sample pieces are required.

Within a day after receiving the lab dips or samples, the buyer should provide the feedback.

.png)

.png)

.png)

.png)

.png)

Pre-Production Approval

It is required to submit a 2-to-3-meter piece of fabric in every color and print to our own fabric testing section before cutting production begins.

For information on the precise requirements and fabric tests that need to be performed, please consult this section of the manual. For the whole spectrum of testing needs, one color and/or print will be used. Only color fastness testing will be necessary for additional colors and prints. We will send the test results to our clients for final approval after testing is finished before allowing cutting. 'Hie client has the ability to reject the lot if the fabrics do not meet their expectations.

At the initial stage of production, all patterns, cutting data and requirements for the finished garment will be provided.

It is required to offer two (2) outfits in each of the sizes according to the client's criteria if mentioned before sewing production gets started. These garments will be inspected for flaws and measured and constructed in accordance with our specifications. Sewing garments requires the use of appropriate fabric, sewing, fasteners, and packaging.

Both the pattern maker and the quality assurance specialist will provide an analysis of the findings. The head of merchandising and the buyer will analyze the results. The go-ahead to start production will be granted after approval. Tire quality assurance specialist will go over any modifications or enhancements that are required.

During the program's production sewing, the TOP process takes place. We will submit one (1) randomly selected item of garments in each size, in a variety of colors, that complies with the requirements. These clothes will be inspected for flaws and compared to our construction and sizing guidehnes. These clothes have to be an accurate depiction of the lot's balance. All of the materials—fabric, stitching, findings, and packaging—must be accurate and indicative of volume. Within two days of receiving the clothing, the quality assurance specialist will provide an analysis of the findings.

In our framework, there are two categories for products. First- and second-quality (in some cases known as irregulars) materials.

Our guiding principle is to put in whatever effort is required to create only top-notch goods. This may entail replacing damaged parts or simply cleaning, patching, and restoring the damaged ones. We have been able to keep quality levels below 1% because of this strategy. We ask that our contractors follow this same attitude in order to keep it going.

Generally, a defect will negatively affect the function, appearance and performance of the garment or create a significant deviation from the standard.

We classify defects into two categories: Major and Minor

All defects listed are considered obnoxious to our customers and will result in rejection if detected insufficient quantity according to our inspection plan

| Material Defects and Damages | Major | Minor |

|---|---|---|

| Rips, holes or cuts on any part of the product | X | |

| Runs and dropped stitches (knits) | X | |

| Snags and pulls | X | |

| Needle chew resulting in fabric weakness | X | |

| Permanent creases on the fabric | X | |

| Bowing/skewing on striped fabrics up to ½% per garment width or length | X | |

| Nap or pile deformation | X | |

| Undesirable odor | X |

| Shading Defects | Major | Minor |

|---|---|---|

| Shade/color match on part to part against standard worse than rating 5 on AATCC gray scale | X | |

| Shade/color match of garment fabric & trim against standard worse than rating 4-5 on AATCC gray scale | X | |

| Dye streaks and barre marks noticeable from 15” distance at critical zone | X | |

| Dye streaks and barre marks not noticeable from 15” distance at critical zone | X | |

| Shade match worse than 5 rating shades on AATCC gray scale | X | |

| Needle chew resulting in fabric weakness | X | |

| Permanent creases on the fabric | X |

| Cleanliness | Major | Minor |

|---|---|---|

| Two or more spots, stains and soil marks larger than 1/8” diameter | X | |

| Two or more spots, stains and soil marks less than 1/8” diameter | X | |

| Multiple thread ends not trimmed | X | |

| Excessive fly &/or contamination on the garment as per QC judgment | X |

| Component Parts & Assembly | Major | Minor |

|---|---|---|

| Missing Parts | X | |

| Missing Operation | X | |

| Operations not done per approval samples and product specification. | X | |

| Any non-conforming component affecting appearance and serviceability | X | |

| Any' component part twisted, distorted, pleated, tight or full, unless specified. | X | |

| Misalignment of parts, pockets, flaps, trims, etc. more than 1/4". | X | |

| Inconsistent nap directions if specified. | X |

| Seams & Stitching | Major | Minor |

|---|---|---|

| A seam shall be considered open when one or more stitches joining a seam are broken or two or more successive skipped lock stitches occur. | ||

| Open seams 1/8" or less | X | |

| Skipped chain stitch | X | |

| Incomplete seam (two or more stitches) | X | |

| Double stitching gap 1/8" or over | X | |

| Needle holes | X | |

| Part of garment caught in unrelated seam operation, distorting fit/appearance | X | |

| Seams twisted, puckered or off-leveled, affecting appearance | X | |

| Improper stitch tension (too loose or tight) that affects appearance | X | |

| Ends of stitching not backstitched, tied, or securely caught in other seams or stitching | X | |

| Raw edges more than 1/16" outside | X | |

| Gauge or edge stitching irregular, i.e. unevenly gauged, affecting appearance | X | |

| Untidy repairs | X | |

| Piecings or joining of binding/div trims on critical zone of garments | X | |

| Monofilament yarn being used as a sewing thread in any type of stitching | X | |

| Seam irritation when in contact with bare skin | X | |

| Seam alignment at jointure exceeding 1/8" | X | |

| Pressing | Major | Minor |

|---|---|---|

| Burned or scorched | X | |

| Over pressed to leave seam impressions or deforming surface effect on the garment | X | |

| Stretched or distorted during pressing | X | |

| Excessive wrinkles that require pressing | X | |

| Serious pressing caused by improper pressing | X |

| Labels, Hangtags and Embroidery | Major | Minor |

|---|---|---|

| Missing or wrong tags, hangtags, price tags, etc. | X | |

| Hang tags insecurely attached or misplaced | X | |

| Wrong main or care label attached | X | |

| Label attached more than 3/8" beyond specified location | X | |

| Label sewn with monofilament yarn | X | |

| Label sewing thread does not match color | X | |

| Label sewing seam uneven, puckered and 1/8” or more away from label edge. | X | |

| Harsh or stiff label compared to approved sample | X | |

| Label omitted or insecurely attached | X | |

| Label sewn beyond label edge | X | |

| Bobbin and needle thread color not matching fabric and label or emblem color respectively | X |

| Symmetry of Pockets | Major | Minor |

|---|---|---|

| Not in a specified location by more than W' | X | |

| Shaped poorly | X | |

| Set or sewn crooked | X | |

| Not of specified size or shape; size in excess of 1/4" | X | |

| Edge margin of stitching not uniform | X | |

| Flaps not properly placed | X | |

| Puckers at the flap joints | X | |

| Slanted pocket flaps (not per specification) | X |

| Collars and Cuffs | Major | Minor |

|---|---|---|

| Fullness or puckers at collar placement | X | |

| Collar points not uniform or balanced | X | |

| Serious puckers on collar joining | X | |

| Misaligned, crooked collar setting more than 3/16" | X | |

| Puckered and or crooked top stitching | X | |

| Pleated and or puckered cuffs at sleeve joint in woven cuffs | X | |

| Fullness or twist of cuff affecting appearance | X | |

| Misaligned cuffs at bottom | X | |

| Rib collar or cuffs set too tight, so do not have enough stretch | X |

| Plackets | Major | Minor |

|---|---|---|

| Top and bottom placket length not equal: | ||

| Top not covering bottom | X | |

| Top 1/4" longer than bottom | X | |

| Top over 1/4" longer than bottom | X | |

| Dimple at the bottom of placket easily visible within 3 feet | X | |

| Unbalanced and crooked placket top stitch | X | |

| Top placket not covering up bottom placket by more than 1/8" for shirts and 3/16" for sweaters | X |

| Stripes, Checks and Piping Matches | Major | Minor |

|---|---|---|

| Stripes not matched as specified: | ||

| Up to 1/4" | X | |

| Over 1/4" | X |

| Closures | Major | Minor |

|---|---|---|

| Buttons missing and /or damaged | X | |

| Buttons misplaced and/or misaligned, causing poor appearance and distortion | X | |

| Buttons not sewn securely (easily pulled off) | X | |

| Buttons not specified size, type or color | X | |

| Buttonholes omitted or added | X | |

| Buttonholes uncut | X | |

| Buttonholes misplaced or not aligned as specified, causing bad appearance | X | |

| Buttonholes not sewn securely ( easily unravel) | X | |

| Defective snaps or fasteners that do not function | X | |

| Misalignment of fasteners, causing bad appearance | X | |

| Snaps and grommets that are not properly set | X | |

| Snaps that do not fasten properly and/or release very easily | X | |

| Improper zipper setting, causing wavy and bumpy appearance | X | |

| Wrong size, type, color zipper | X | |

| Defective zipper sliders | X | |

| Defective zipper stops on open front jackets | X | |

| Tight clearance between the slider and the seam edge causing slider to operate with difficulty | X | |

| Rivets not properly and securely set | X | |

| Rivets with rough edges | X |

| Finishing & Hand | Major | Minor |

|---|---|---|

| Permanent wrinkles and/or deformation on ±e garment | X | |

| Pressed poorly or not pressed at all | X | |

| Over-pressed and/or improperly finished to deform shapes, designs or patterns on the fabric surface | X |

| Finishing & Hand | Major | Minor |

|---|---|---|

| Not as specified per product spec and /or general product performance standard | X |

| Measurements | Major | Minor |

|---|---|---|

| Any measurement beyond specified tolerances per product specification sheet | X |

| Design & Color way | Major | Minor |

|---|---|---|

| Not according to approved sample or specification | X |

| Shipping Carton Mark | Major | Minor |

|---|---|---|

| Wrong and/or incomplete shipping carton markings | X |

We highly believe that a quality control framework has to be placed in the process of manufacturing. These frameworks with variations may be planned, assessed and implemented by our Quality Control Specialist. The three fundamental frameworks which we work on are:

| Test | Test Methods | Woven Requirements | Knit Requirements | |

|---|---|---|---|---|

| Shrinkage (dimensional changes after 3 home launderings) | AATCC 135-2004 | Length Width |

Maximum 4% Maximum 2% |

Maximum 6% Maximum 6% |

| Appearance after 3 home launderings | AATCC 135-2004 | Shade change Wrinkling Pilling Cross Staining |

4.0 4.0 4.5 5.0 |

4.0 4.0 4.0 5.0 |

| Pilling | ASTM D3512-2005 | 30 minute random pill test | 4.0 | 3.0 |

| Color Fastness to crocking | ATTCC 8-2005 | Dry Wet | 4.0 3.0 |

4.0 3.0 |

| Color Fastness to Laundering | AATCC 61-2003 test # 2A | Change in shade Staining on multi fiber: acetate cotton nylon polyester acrylic wool | 4.0 3.0 3.0 3.0 3.0 3.0 3.0 |

4.0 3.0 3.0 3.0 3.0 3.0 3.0 |

| Color Fastness to light | ATCC 16-2004 | Rating after 20 AFU | 3.5 | 3.5 |

| Color Fastness to non-chlorine and chlorine bleach | AATCC TS- 001 | 4.0 | 4.0 | |

| Fiber Content | AATCC 20A-2005 | Fiber name | +/- 3% | +/- 3% |

| Fabric Weight | ASTM D3776-2002 | Oz/sqyd or gm/m2 | +/-5% | +/- 5% |

| Thread Count | ASTM D3775-2OO3 (Woven) ASTM D'3887-1999 (Knit) | +/- 5% | +/-5% | |

| Yarn Count | ASTM D1059-2001 | +/-10% | +/- 10% | |

| Tear Strength | ASTM D1424-2004 | Warp Weft |

3.0 lbs 2.5 lbs |

N/A |

| Tensile Strength | ASTM D5034-200 1 ASTM D3786-8 7 | Warp Weft |

50 lbs 40 lbs |

40 lbs |

| Shade Uniformity | Visual Test Method | Uniform and even color within sample | Uniform and even color within sample | |

| Flammability | 16 CFR1610 | Class 1 | Class 1 | |

| PH value | AATCC 811996 | PH of between 5-9 originally (before washing) | PH of between 5-9 originally (before washing) | |

| Soil Release | AATCC 130-1995 | 3.5 | N/A |

SPI (stitches per inch)

| Shirt | Front Length Total Chest Shoulder to Shoulder Sleeve Length Center Back Cap |

+/-1 inch +/-1 inch +/- 1/2 inch +/- 1/2 inch +/- 1/4 inch |

| Pants/Skirts | Total sleeve opening Total sweep Neck width Back neck drop Front neck drop Pocket length Pocket width Waist relaxed Waist stretched Hip Front rise Back rise Inseam Total leg opening Total thigh Knee Front skirt length Drawstring Total Sweep Back clastic finish |

+/- 1/4 inch +/- 1 inch +/- 1/8 inch +/- 1/8 inch +/- 1/8 inch +/- 1/8 inch +/- 1/8 inch +/- 1 inch +/- 1 inch +/- 1 inch +/- 7+ inch +/- 1/4 inch +/- 1 inch +/- 1/4 inch +/- 1/2 inch +/- 1/2 inch +/- 1/4 inch +/- 2 inches +/- 1 inch +/- 1/2 inch |

| Others | Back Elastic Length Front band height Opening stretched Opening relaxed Top crown length Top crown width C.F. headband height Headband length Tie extension |

+/- 1/4 inch +/- 1/4 inch +/-1 inch +/-1 inch +/- 1/4 inch +/- 1/4 inch +/- 1/8 inch +/- 1/2 inch +/- 1/2 inch |

Utilizing U.S. military standard 105E, single arrange, level 1, ordinary 2.5 A.Q.L, method of audit, a sample is procured randomly by placing a purchase order. It is mandatory that the Lest determination be arbitrary and scores to a least of 25% of the bundles or cases within the P.O. number.

Four ranges ought to be part of this audit: cut precision, failure defects, component shading, and tally.

The sample's selected components will be placed on the checking. We identify problems for measurements that exist outside of the allowance by using the cut-piece resistances. Should there be any problem with the sample—such as a dimensional issue—that could potentially arise in the final garment, it will lead to "rejection." Re-bundling and a 100% review are part of this. If there are no problems during testing, the cut can be submitted to be sewed.

When assessing the cut pieces, we consult the section of the handbook dedicated to Garment Inspection Material Defects and Damages and Cleanliness. A lot of these defects have different levels of severity. Making judgments in this audit phase is done as though the components were finished clothes at the conclusion of the manufacturing process.

We make sure to verify and incorporate every element into the audit. A cut of tops, for instance, would have sleeves, cuffs, facing, front and back bodies, etc. Inevitably there will be slight changes in shade, but it's crucial to recognize significant ones. Before stitching, certain packing techniques can be required to prevent colored components.

The initial phase in the sample selection procedure should involve measuring the accuracy of the bundles. It is necessary to replace any defective components to ensure precision and uniformity for the sewing floor.

Quality control officers conduct inspections using the statistical Military standard sample plan, level 1, which is based on 2.5 A.Q.L. Throughout the day, inspections are carried out with an emphasis on the operator and the operation. Instead of reporting to the sewing supervisor, the quality inspector ought to report to a quality supervisor. When necessary, the inspectors will help the sewing supervisor implement correct we measures. It is widely believed that one inspector for every 25 to 40 operators provides enough floor coverage. The bundles that are to be inspected should be brought to an illuminated investigation table either inside the sewing line or next to it. The following is the real inspection procedure:

A final audit plan that evaluates appearance, measurements, construction, craftsmanship, and packaging to ensure that our garments meet client requirements. The Military standard 105E, single plan, level 2, normal 2.5 A.Q.L. forms the foundation for the final audit process. The audit will be conducted on packaged and stitched goods. Before auditing, it is advised that the clothing be folded, bagged, stickered, and box cased with a license plate.

A well-lit space with a table big enough to lay out clothes and take measurements are used for the audit. For the inspection procedure, the client's specification sheets, PO numbers, quantities, and case count must be available. The following is the audit procedure:

We also acknowledge that it is necessary to arrange and successfully complete an inspection with TUV SUD, also referred to as a "3rd Party Inspector," before the final product is shipped to clients. The Client bears the responsibility for all inspection-related expenditures.

| L | W | H |

|---|---|---|

| 33" | 23.5" | 25.5" |

Situated at the junction of modernity and tradition, Kolkata is a thriving manufacturing and commercial city in India that presents distinct benefits for clothing makers. This ancient city, also known as the "City of Joy," has long been a hub for business and industry, which makes it the perfect place for our activities.

Here are six benefits you should be aware of whether you make goods for a global market or are thinking about investigating how India can benefit your company.

To meet the needs of our customers, we provide a variety of flexible shipping options, such as FOB, CNF, CIF, and EXW.

The buyer may choose for shipments to be done by air or sea. Although Chennai is our preferred port, buyers are free to select the port of loading that best suits them.